As the second-largest-selling car brand in the UK for more than two decades, Vauxhall’s headquarters in Luton produces a staggering 100,000 vehicle units a year. Reliability and efficiency of equipment needed to help produce such huge numbers is essential. SERAPID was approached by Vauxhall, a subsidiary of Group PSA, to help solve repeated issues of reliability with existing goods lifts at its manufacturing plant. The existing hydraulic drive system was not controlled enough, causing damage to lift entrances, stacker trucks and operatives when loading and unloading. This, combined with a frequent need for maintenance causing disruption to production, meant a total refurbishment and modernisation was required.

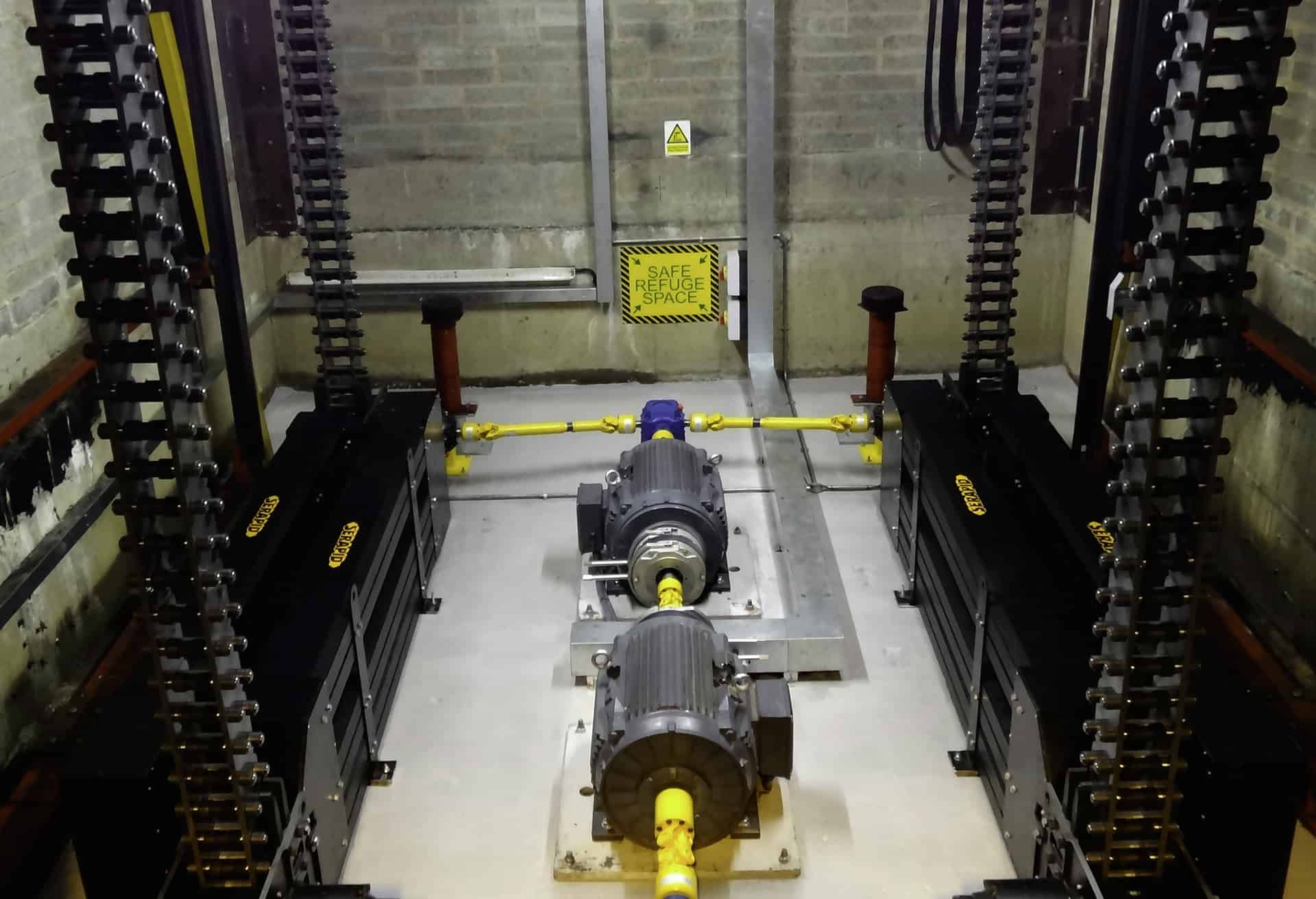

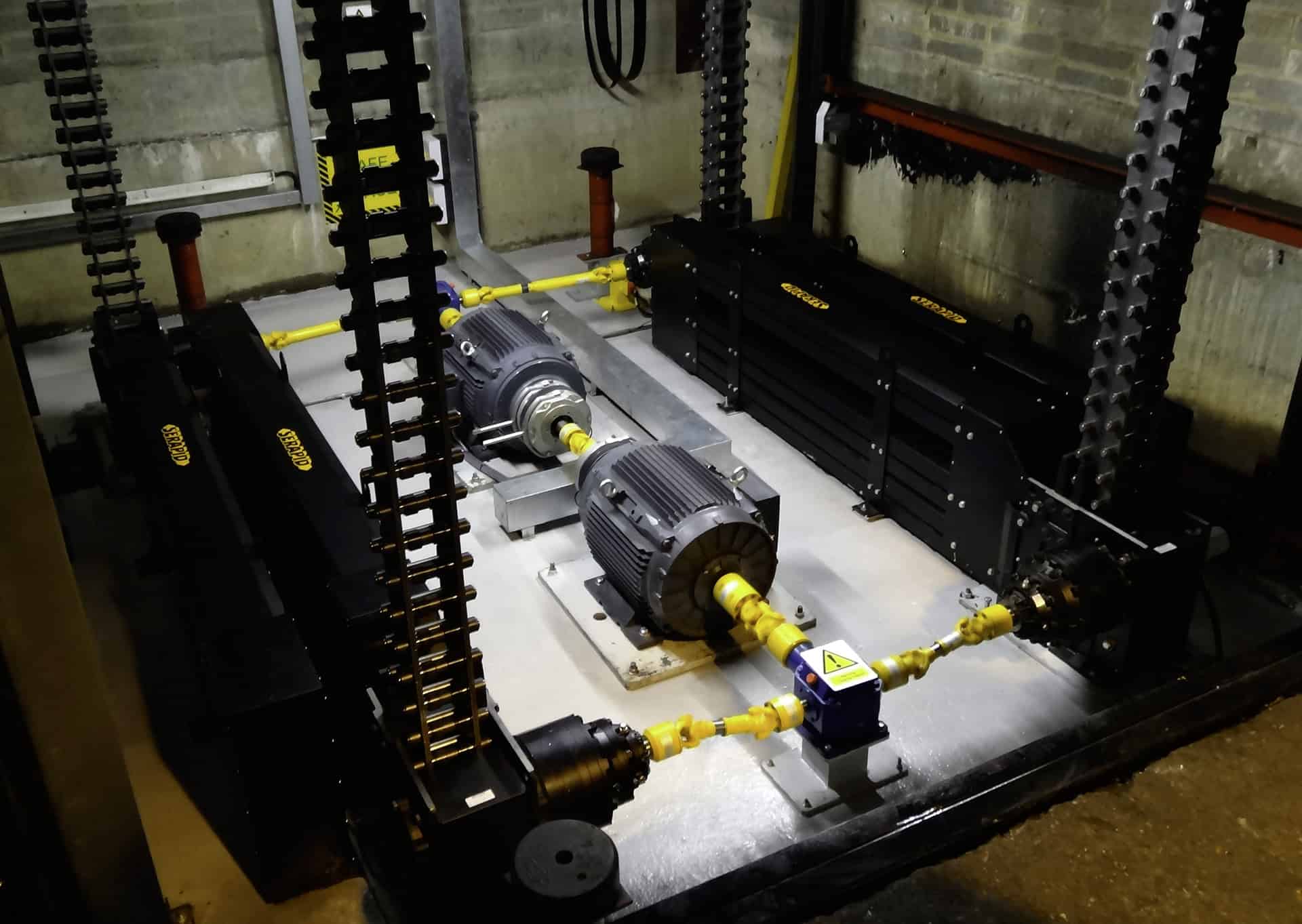

SERAPID’s LinkLift electro-mechanical technology was the perfect alternative solution. Based on a non-hydraulic system, the LinkLift rigid chain scissor lift technology is incompressible and absolutely robust. Installed into goods and car lifts at the production plant it can sustain loads of up to 10 tonnes with stability and precise positioning control. Replacing the cabin on the platform lifts too, this total retro-fit of the lift drive systems into a mechanical solution has ensured 100% reliability since; and a sustainable solution for the future.