CLAMPS

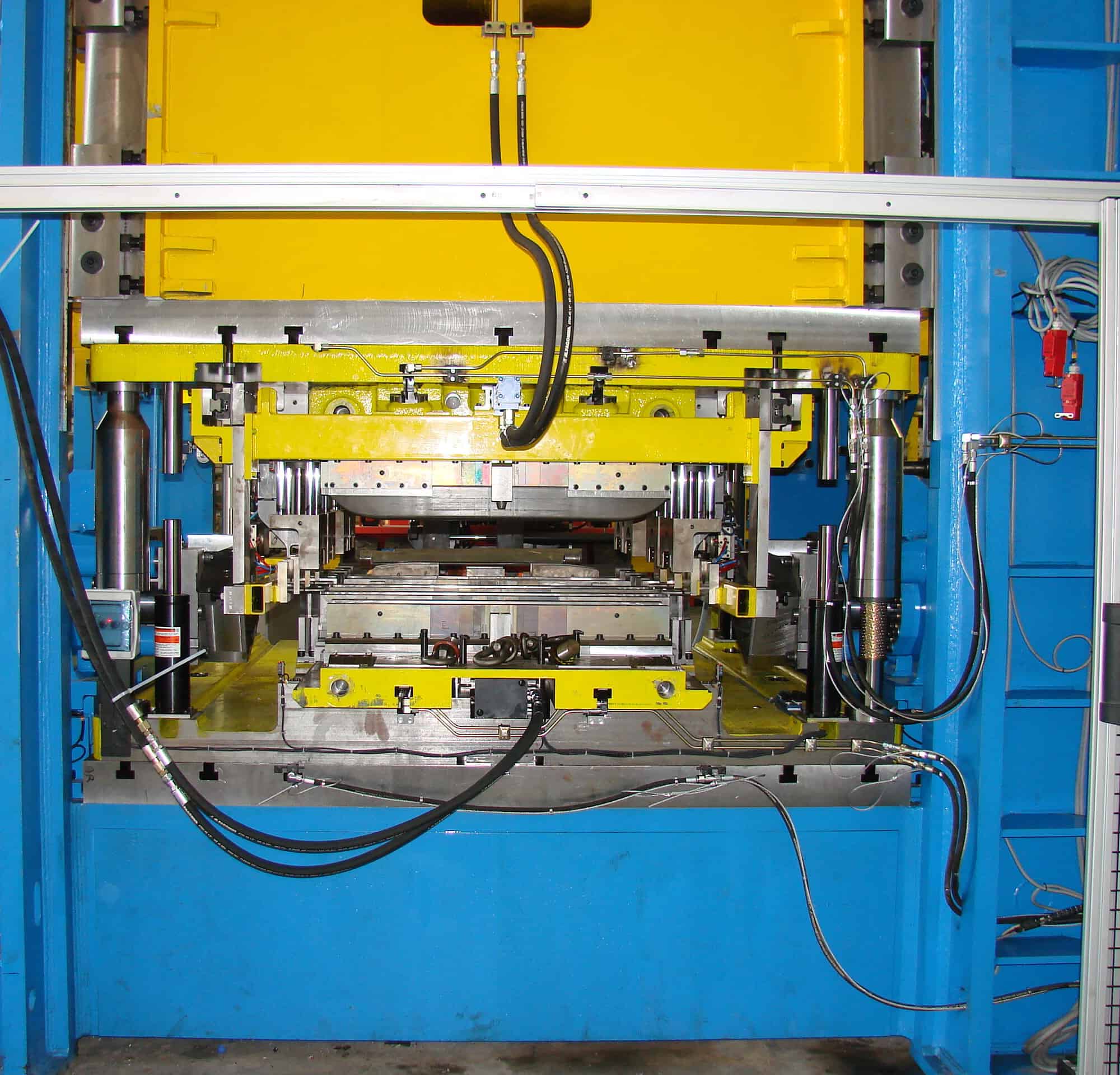

SERAPID offers clamps for both standard and custom applications. Clamping and unclamping can be automatic or require minimal manual intervention. For quick die changes, it is crucial to easily and safely clamp and release the dies, allowing for the quick installation and removal of clamps from the press bolster. Our extensive range of clamps provides effective solutions tailored to your specific application. Optimize your productivity with simple, fast, and efficient die transfer and clamping systems. Our specific solutions can be integrated with Single Minute Exchange of Die (SMED) techniques.

Choosing Clamps

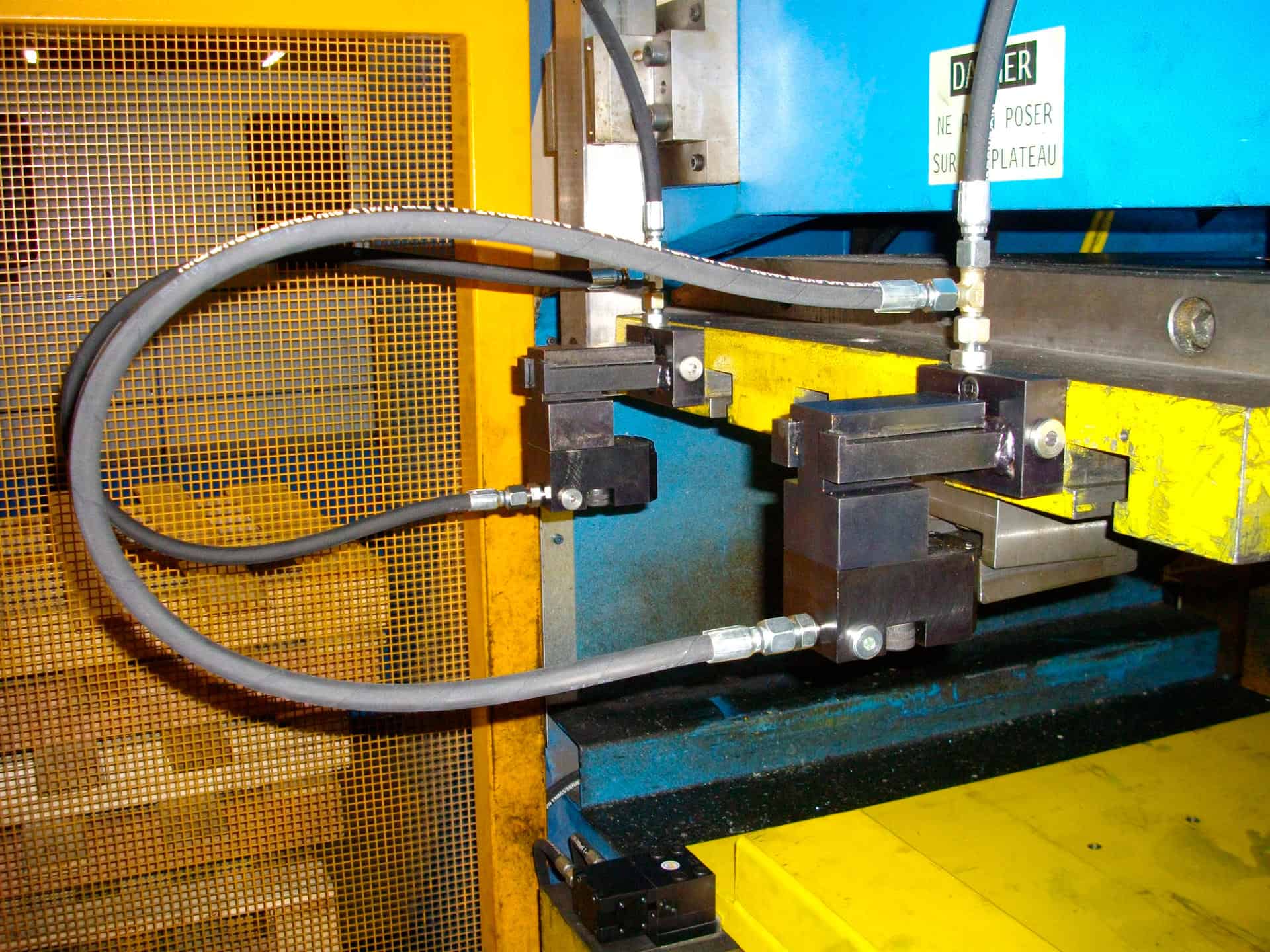

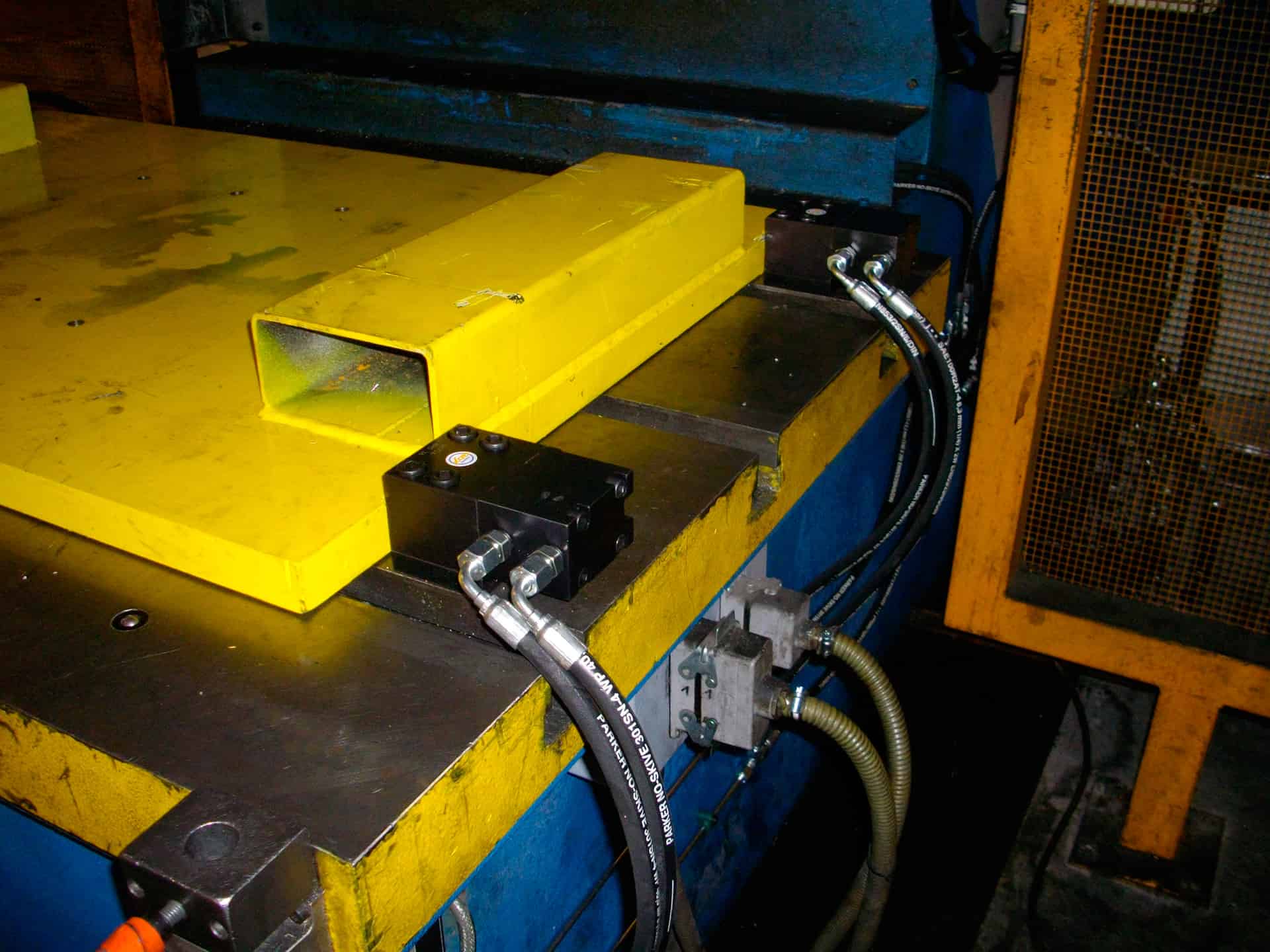

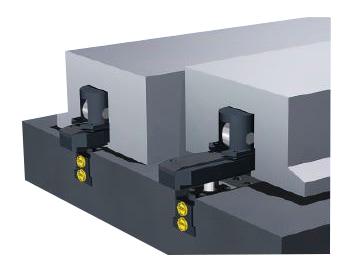

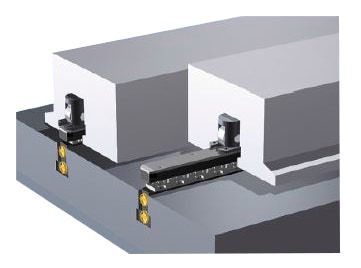

Fixed clamps are permanently integrated into the bolster or ram. When opened, they lift the die, clearing the transfer path. These movements are hydraulic-driven. Fixed clamps enable full automation without additional assistance, but they require die standardization. Most of our clamps are suitable for fully automatic clamping.

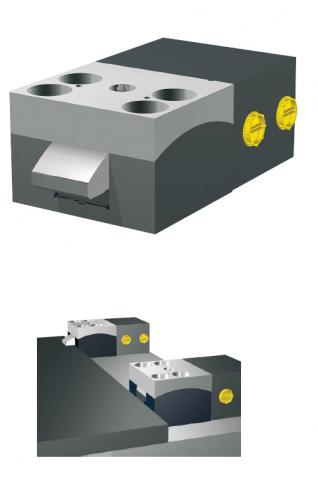

Removable clamps need to be manually removed and re-inserted. This solution is cost-effective and flexible but requires more labor. Removable clamps are lower in cost and more adaptable, but they prevent the automation of the Quick Die Change (QDX) process.

Clamp Position

• Specify the clamp position (sides or front and back).

• Sensors: Some of our clamps can be equipped with sensors to monitor their status.

• Clearing Clamps: When released, the clamp is cleared away from the die body to avoid interfering with the transfer trajectory.

• Built-in: When released, the clamp is retracted into the press bolster or a T-slot. This is used for dies as wide as the bolster or when a removable bolster needs to be reused. These clamps require standardized clamping points and suitable holes or T-slots in the dies.

• Clamps with Roller Ramps: The clamping system is combined with roller ramps for precise die positioning.

• Clamping Height: Distance covered by the clamp until it closes. Automation Capacity: Most of our clamps facilitate complete QDX automation.

Power Supply

Our clamps can be activated in three different ways:

• Hydraulic Tightening and Release: This type provides better efficiency and, depending on installation specifics, can offer active safety functions or better use of available machine space.

• Hydraulic Clamping with Spring Release: This solution can be used for full automation in some cases. Pressure can be controlled to complete the safety mechanism.

• Mechanical Clamping with Hydraulic Release: A simple and reliable solution. However, the clamps need to be positioned manually.

Hydraulic Power Supply: Standard G1/4", also available in UNF 9/16".